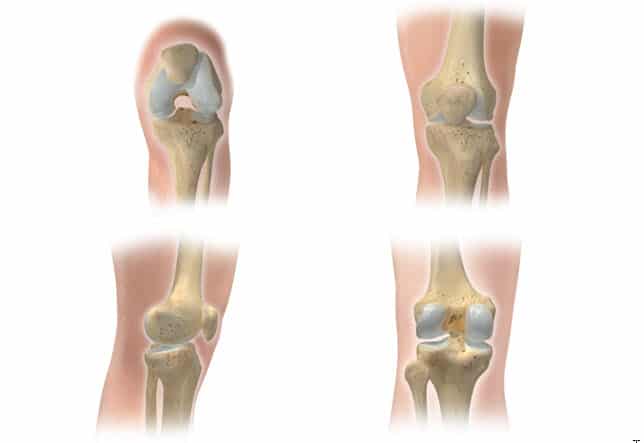

Modern total knee replacement surgery has been a safe and effective treatment for end-stage symptomatic severe knee arthritis.

Listen to my patient Miriam, as she tells you about her custom knee replacement surgery…

A desire to further improve patient functionality and satisfaction after knee replacement has pushed technology to develop better implants and instrumentation. This has been a journey in the world of knee replacement surgery.

The journey of modern knee replacement surgery started with off-the-shelf implants that were comprised only of three sizes!

Today while using off the shelf implants, we have several sizes available for intraoperative decision making. The implant companies and surgeons traditionally thought and hoped the patient fit the prosthesis rather than the other way round!

The implant industry then moved on to having numerous implant sizes that would fit on to the variable knee sizes that patients have. Along the way, it came “gender” implants designed by Zimmer where the medial lateral and anterior-posterior dimensions were better suited for a particular “gender”.

Since every knee has its unique anatomy, logically it seems that customizing the knee should improve the outcomes. The development of “customization” in knee replacement surgery has been a continuum.

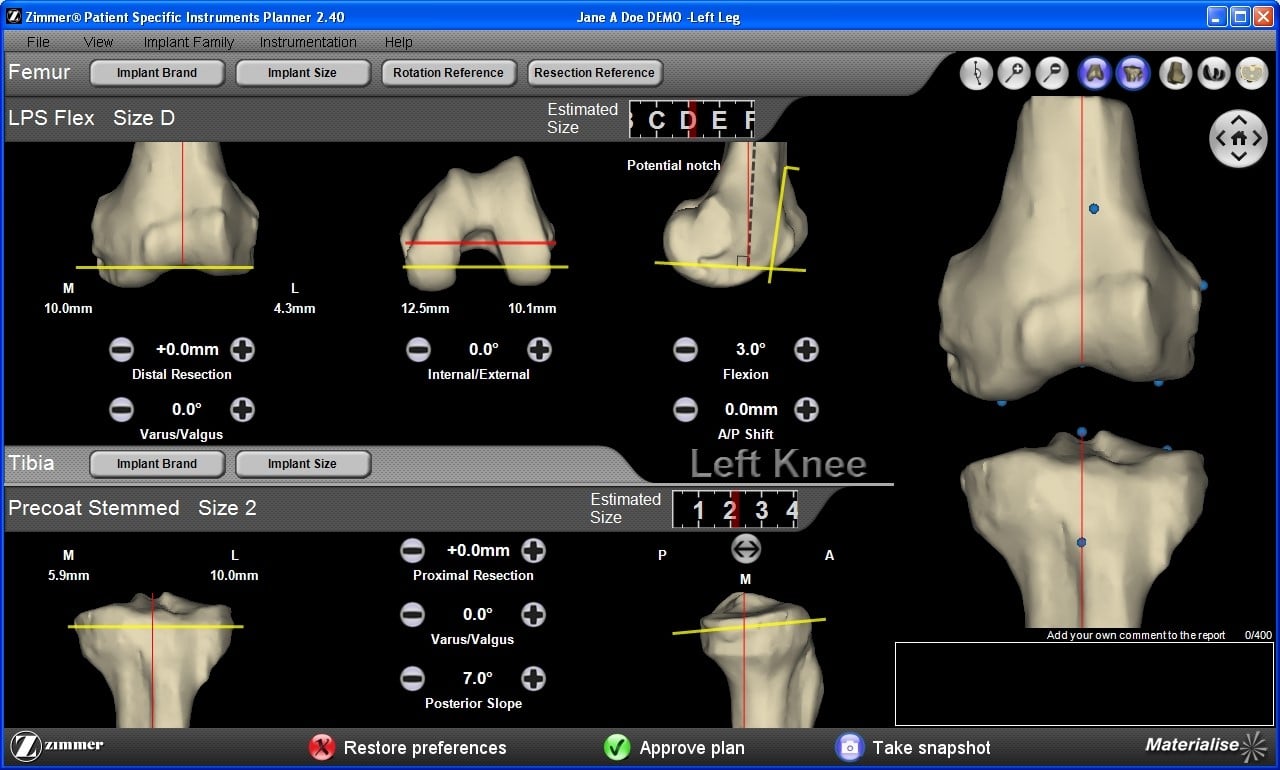

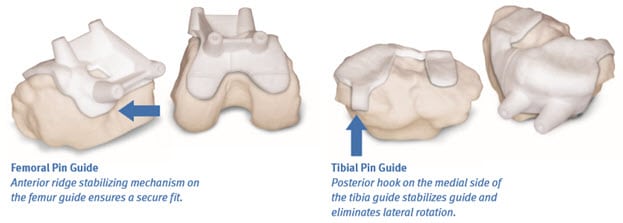

The first enhancement in technology for customization came with the development of “patient specific guides”, “Personalized Guides”, “PSI” or “patient specific instrumentation”. This was designed by Zimmer, in which the knee underwent MRI (or CT scan if the patient was not a candidate to get a MRI) and the individual cutting guides (guides are the instrumentation that is used to remove the diseased part of the bone) were made specifically for the patient).

These individual cutting guides adapted very well to the anatomy of the patient and made the surgery a little less invasive. The decrease in invasiveness was because the bone did not have to be drilled for placement of guides into the bone as we did with the traditional knee implants.

This was because the instrumentation conformed to the part of the knee joint that was exposed during the surgery and the instrumentation accounted for the anatomy of the bone beyond the knee, which has not seen during the surgical exposure.

The surgeon and the implant representative do the surgical planning. The surgeon can view the patient’s anatomy and have a customized surgical plan for each patient.

The customized instrumentation conforms well with the bone and helps the surgeon to remove the diseased part of the bone.

The off the shelf implant is inserted after the diseased part of the bone is removed.

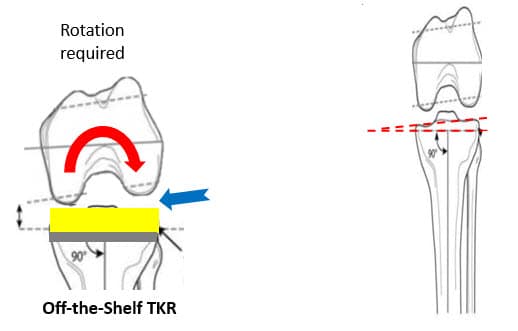

One of the intra operative battles has been matching the size of the patients knee with the size of the implant that is to be implanted.

Off the shelf implants sometimes do not fit perfectly. This imperfection is one of the reasons perceived as the reason for residual pain after knee replacement surgery.

With “off the shelf’ knees, the surgeon is sometimes “in between sizes”. Implant may have an “overhang” and is responsible for residual pain. Additionally, the joint line, rotation, size, reference points many need compromise.

The rotation may be incorrect and there maybe some step off between medical and lateral side with non-customized implants.

Rotation of the implant is decided by intra operative landmarks as well as landmarks that go beyond the surgical field (like head of the femur). The surgeon cannot look at the landmarks that are not visible. The surgeon therefore makes approximations and may sometimes compromises on how much to rotate and how to align the artificial knee.

Additionally, the artificial joint line many not replicate the native joint line leading to ligamentous play. The custom knee has off set plastic that helps restore the native joint line.

Incorrect rotation from off the shelf implant is perceived as another reason for residual pain after total knee replacement.

The subsequent advancement was development of the customized implant along with the customized instrumentation. The thought process is that if a knee is manufactured to match the native anatomy of the knee without the arthritis, the knee would feel more natural. We have custom clothes, customized houses, custom kitchens and now we have custom artificial joints!

Every knee is unique. Every knee has its own geometry.

The custom knee implant is made specifically for the patient based on the patient’s own anatomy. These custom implants are placed in the patient using customized instrumentation. The idea is that these customized implants placed in the patient with customized instrumentation will better replicate the patient’s own kinematics.

The major distinguishing factor between the custom implant and the patient’s specific instrumentation is that the actual knee that is implanted in the patient is customized, it is not only the instrumentation.

The patient undergoes a CT scan of the knee and the actual knee implant is made from a model of the CT scan.

The CT scan accounts for the alignment of the lower extremity

The instrumentation for removing the diseased bone is also customized. It comes to the operating room as a pre sterilized, disposable tray.

This custom knee is made for that particular patient and cannot fit any other patient. There are no sizes. Custom implants recreate patients own anatomy. It is one patient and one implant. Designed to fit the patient’s knee only- no one elses. The artificial knee is better supported with use of the correct size. Who can argue against having the right size?

The “cut out” of the custom knee conforms to the native knee. The implant also have the same geometry of the native knee. It is made from a mold that matches the naïve knee. This mold can be handed to the patient after the surgery.

This the “posterior stabilized” knee which implied that the posterior cruciate ligament is substituted. The “Posterior stabilized” was the last in the designs that were manufactured by commercial custom knee manufacture company. I used only the posterior stabilized version. The reasons for preferring this design are in the FAQs.

Off the shelf implant is sometimes larger or smaller than the native bone. There maybe an overhang that can cause residual pain and stiffness. This problem is entirely eliminated with a custom implant. There is no intra operative decision to place larger or smaller implant- there is only one implant!

This customized knee is more likely to replicate the natural kinematics of the knee joint leading to better patient satisfaction. Custom implant recreates shape as well as the fit. It’s not only the size but the shape that matters in improving function.

The motion of the artificial knee replicates the motion of the native joint that was replaced. “Balancing soft tissues” is step in knee replacement surgery when the surgeon insures that the tension in the ligaments is the same throughout the range of motion. This is not an issue with customized knees. Most of the times, the ligaments balance themselves.

The “cam post engagement” is different ie – the plastic engages with the metal in a better manner. The “roll back” as the knee bends occurs based on articulating surfaces.

I personally like the “fit and feel” of how the knee moves intro operatively.

I get to see a surgical plan before the surgery. The printout shows a good representation of alignment, cuts on the bone, how much bone gets resected, how the jigs sit on the bone and how the final implant looks on the knee before starting the surgery.

Additional advantages are that the custom implant is more bone conserving, it is less invasive to place the implant into the body because of the customized instrumentation. Additionally because the implant covers good part of the cancellous bone that is exposed, there is less blood loss during and after the surgery

My hope is this page along with the related frequently asked questions should provide the most comprehensive information about custom knee replacement. I have covered the brief history, design progression, design rationale and some case studies. I have been using custom implants long before “commercially available” custom knee implants and the company that currently makes them were in existence.

Customized femoral component along with 3D printed bone model

The image above shows a custom patient-specific femoral component along with a 3D printed bone model depicting the patient’s unique anatomy.

Different types of polyethylene inserts

The choice of polyethylene insert used depends upon the native stability of the diseased joint and stability achieved during the surgery. With an increased degree of constraint, there is increased wear and tear of the polyethylene insert.

Custom Knee Replacement FAQ’s

- Do all patients get a customized knee replacement, if not why not?

- Why does my surgeon not do a customized knee replacement?

- How long does the swelling last after knee replacement surgery?

Find out the answers to these and other questions here.

Why choose Dr. Karkare?

As a top joint replacement specialist in New York City, Dr. Karkare has a stellar reputation, extensive experience, ensuring patients have the broadest array of safe and effective treatment options to relieve pain and other symptoms.

This enables every patient to make an informed, educated decision so they can feel confident in their care every step of the way.

To schedule your evaluation, call (516) 735-4032 or use our online contact form to learn more.

How Can I Help You?